Skip to content

This logo was marked on a piece of metal

This logo was marked on a piece of metal

This computer fan shows the details of the laser cutting

This computer fan shows the details of the laser cutting

USMC retirement gift.

Engraved on all 4 sides

USMC retirement gift.

Engraved on all 4 sides

Laser engraved slide for a firearm

Laser engraved slide for a firearm

This piece shows an engraving on the left and the inlay on the right

This piece shows an engraving on the left and the inlay on the right

We personalize your bracelet created by you or chosen from our templates

We personalize your bracelet created by you or chosen from our templates

You can customize your clasp as well!

You can customize your clasp as well!

This plate was engraved as part of a beautiful wind chime

This plate was engraved as part of a beautiful wind chime

Step one of wood inlay - keep looking for a picture of the finished product!

Step one of wood inlay - keep looking for a picture of the finished product!

Step two - perfect insertion of the inlay. Our method ensures a perfect fit.

Step two - perfect insertion of the inlay. Our method ensures a perfect fit.

The finished prodcut! We can't take the credit on this one though - the owner; Cut Chop Serve in Charlotte is very talented.

The finished prodcut! We can't take the credit on this one though - the owner; Cut Chop Serve in Charlotte is very talented.

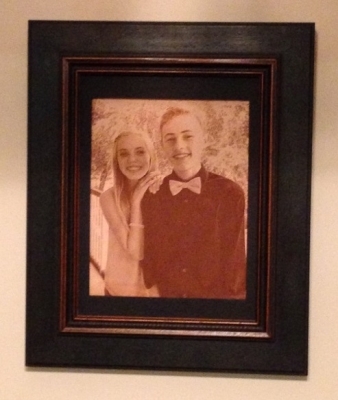

This picture was engraved onto a piece of leather. Makes for a very nice, detailed and different piece to put onto your walls!

This picture was engraved onto a piece of leather. Makes for a very nice, detailed and different piece to put onto your walls!

Logo laser engraved onto motor plate.

Logo laser engraved onto motor plate.

This knife was also engraved as a closing gift however we can engrave a knife for the chef of your family!

This knife was also engraved as a closing gift however we can engrave a knife for the chef of your family!

Two thickness gaskets were created for a customer to fit over this piece.

Two thickness gaskets were created for a customer to fit over this piece.

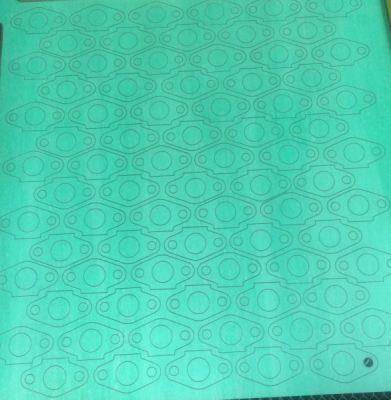

We were able to utilize as much of this gasket material to produce the previous product.

We were able to utilize as much of this gasket material to produce the previous product.

We can also do granite engraving like this closing gift from a Realtor.

We can also do granite engraving like this closing gift from a Realtor.

Wood engraving can show different textures and shading of the wood.

Wood engraving can show different textures and shading of the wood.

This 3D laser engraving was the perfect match for this skateboard project!

This 3D laser engraving was the perfect match for this skateboard project!

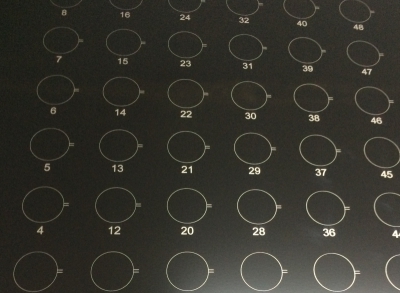

On this product the customer had already outlined the circles, we added the slash marks and numbers. This material was anodized aluminum.

On this product the customer had already outlined the circles, we added the slash marks and numbers. This material was anodized aluminum.

A closer look of the finished product of the above picture with added final markings for the customer.

A closer look of the finished product of the above picture with added final markings for the customer.

The coated metal on this slide was engraved with the CO2 laser as well.

The coated metal on this slide was engraved with the CO2 laser as well.

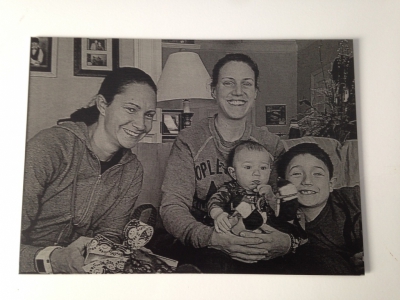

What a great way to share family pictures! Our CO2 laser was used to engrave this picture on anodized aluminum.

What a great way to share family pictures! Our CO2 laser was used to engrave this picture on anodized aluminum.

This dinosaur was 3D CO2 laser cut on .130" foam board.

This dinosaur was 3D CO2 laser cut on .130" foam board.

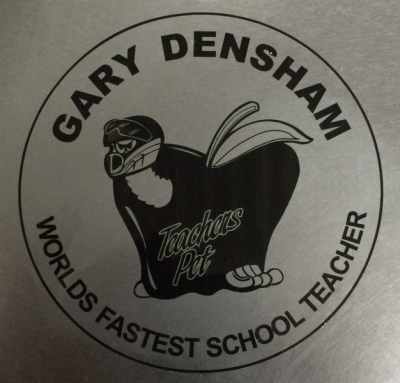

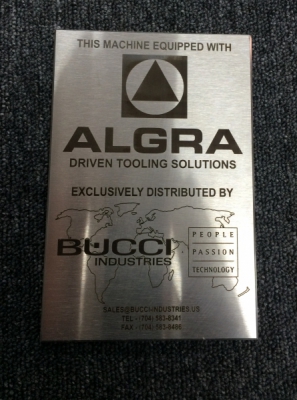

One of our customers needed to identify their ownership of the tooling. We engraved this on a brushed stainless steel plate.

One of our customers needed to identify their ownership of the tooling. We engraved this on a brushed stainless steel plate.

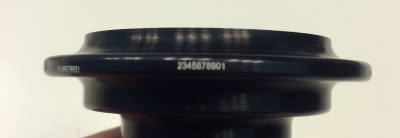

We engraved this serial number as a test part for a customer on a very thin area. We had to ensure smallest writing possible yet still legible to the eye.

We engraved this serial number as a test part for a customer on a very thin area. We had to ensure smallest writing possible yet still legible to the eye.